Imagine being able to replace a broken glass with just the click of a button. 3-D printing technology is revolutionizing the way we think about replacing broken items, including glassware. With the ability to print complex designs and shapes, this technology is making it possible to recreate delicate glass items with ease.

The concept of using 3-D printing for glass replacement is not only innovative but also practical. It eliminates the need to search for exact replacements or dispose of broken pieces. This technology is poised to change the way we handle broken glassware, making it a fascinating area to explore further.

Key Takeaways

- 3-D printing technology can be used to replace broken glassware.

- This technology allows for the creation of complex glass designs.

- Glass replacement through 3-D printing is both innovative and practical.

- It reduces the need to search for exact replacements or dispose of broken glass.

- The technology is expected to revolutionize how we handle broken glass items.

The Current Challenges of Broken Glassware

The challenge of dealing with broken glassware is multifaceted, involving not just the immediate loss but also the long-term environmental impact. Broken glassware is a ubiquitous problem that affects households and businesses alike.

Common Problems with Traditional Glass Replacement

Traditional methods of replacing broken glassware often involve a tedious search for an exact match, which can be time-consuming and sometimes futile. As one expert notes, “The inability to find a precise replacement can lead to significant inconvenience and additional costs.”

Environmental Impact of Glass Waste

The environmental implications of glass waste are substantial. Glass does not biodegrade and can remain in landfills for centuries. The production of new glass to replace broken items also consumes significant amounts of energy and raw materials.

The Need for Innovative Solutions

Given these challenges, there’s a clear need for innovative glass repair methods. Technologies like 3D printing offer promising solutions, potentially reducing waste and improving the efficiency of glass replacement.

Broke a Glass? Someday You Might 3-D-Print a New One

As 3D printing advances, the possibility of printing glass becomes increasingly tangible. This technology has the potential to revolutionize how we replace broken glassware, making it easier to restore our favorite items.

Understanding Glass 3D Printing Technology

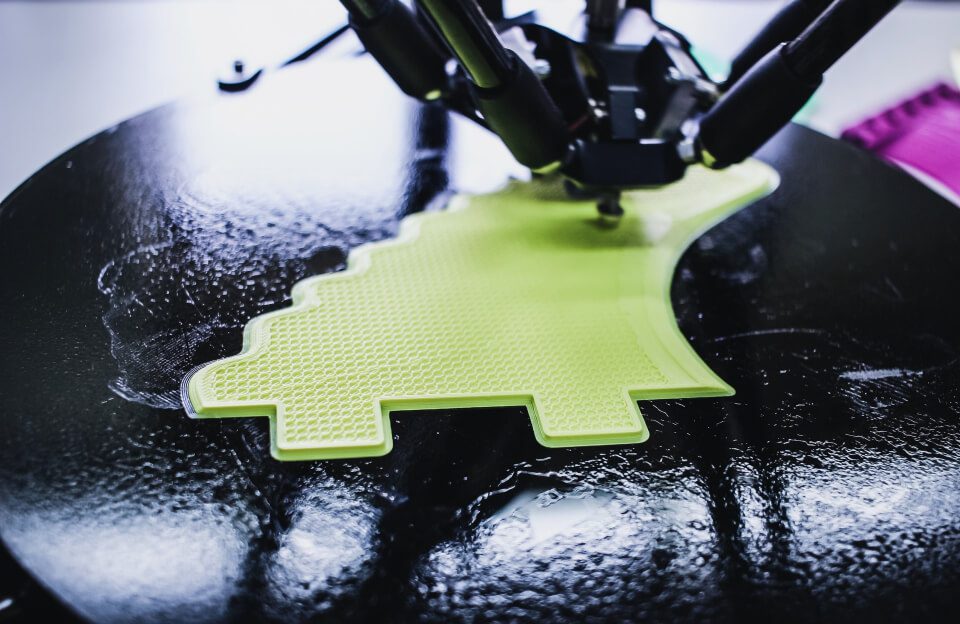

Glass 3D printing involves complex processes, starting with the material science behind printable glass. Researchers have been working on developing glass materials that can be used in 3D printing, focusing on achieving the right consistency and durability.

Material Science Behind Printable Glass

The development of printable glass involves creating a material that can be melted and shaped by a 3D printer. This requires a deep understanding of glass chemistry and the ability to formulate a material that meets the necessary criteria for 3D printing.

Printing Processes and Techniques

Various printing processes are being explored for glass, including selective laser sintering and stereolithography. Each technique has its advantages and challenges, particularly in achieving the desired level of detail and structural integrity.

Recent Breakthroughs in the Field

Recent years have seen significant breakthroughs in glass 3D printing, both in academic research and industry developments. These advancements are bringing us closer to the reality of being able to 3D print glass objects, including replacement parts for broken glassware.

Academic Research Highlights

Academic research has focused on improving the material properties of printable glass and enhancing printing techniques. Studies have shown promising results in creating complex glass structures.

Industry Developments

Industry players are also making significant strides, with companies investing in the development of commercial glass 3D printing technologies. These developments are crucial for making glass 3D printing a viable option for consumers and industries alike.

Practical Applications and Current Limitations

The advent of 3-D printing technology is revolutionizing the way we replace broken glassware. This innovative technique promises to simplify the process, making it more efficient and less wasteful.

As we explore the potential of 3-D printing in glass replacement, it’s essential to consider both its practical applications and the limitations that currently exist.

Potential Home and Consumer Uses

For consumers, 3-D printing could mean that a broken glass or window can be replaced at home, or by visiting a local printing service. This could significantly reduce the time and hassle associated with traditional replacement methods.

Advanced glass repair solutions could become more accessible, making it easier for people to restore their belongings without needing specialized equipment.

Industrial and Commercial Applications

Industrially, 3-D printing of glass could revolutionize manufacturing processes, enabling the rapid production of complex glass components.

This could have significant implications for industries such as construction, automotive, and electronics, where glass is a critical material.

Current Challenges to Overcome

Despite the potential, there are several challenges to overcome before 3-D printing of glass becomes widespread.

Technical Hurdles

One of the main technical hurdles is achieving the desired level of transparency and durability in printed glass.

Current 3-D printing technologies struggle to replicate the fine optical qualities of traditional glass.

Cost Considerations

Another significant challenge is cost. Currently, 3-D printing technology capable of producing high-quality glass is expensive, making it inaccessible for many potential users.

| Application | Current Status | Potential Impact |

|---|---|---|

| Consumer Use | Limited by cost and technology | Convenient replacement of household items |

| Industrial Use | Early adoption in niche areas | Revolution in manufacturing complex glass parts |

Timeline for Consumer Availability

While it’s difficult to predict exactly when 3-D printed glass will become widely available for consumer use, advancements in technology and reductions in cost are expected to drive adoption.

As the technology improves, we can expect to see more consumer-friendly applications emerge.

Conclusion: The Future of Glass Replacement

The advent of 3-D printing technology is poised to revolutionize the way we replace broken glassware. With its potential to produce sustainably printed glass pieces, this innovation could significantly reduce glass waste and the environmental impact associated with traditional glass manufacturing processes.

As research and development in glass 3-D printing continue to advance, we can expect to see practical applications emerge in both consumer and industrial settings. The prospect of being able to print a replacement glass at home or having access to custom-made glass parts could become a reality in the near future.

With companies like Corning and Stratasys at the forefront of this technology, the future of glass replacement looks promising. As this technology becomes more accessible, it is likely to have a significant impact on how we approach glass repair and replacement, making it more sustainable and efficient.